Benefits of 5-axis CNC Machining

November 29, 2021

3D Printing Guide: Tips to Get Started

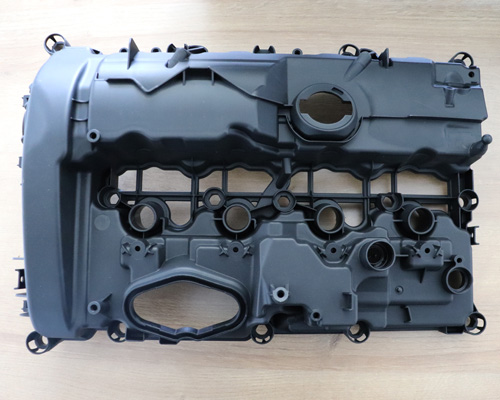

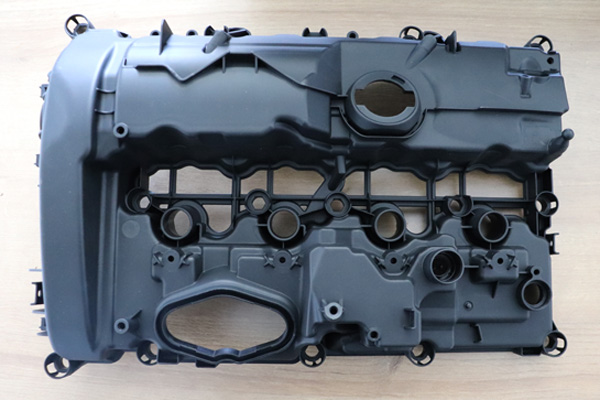

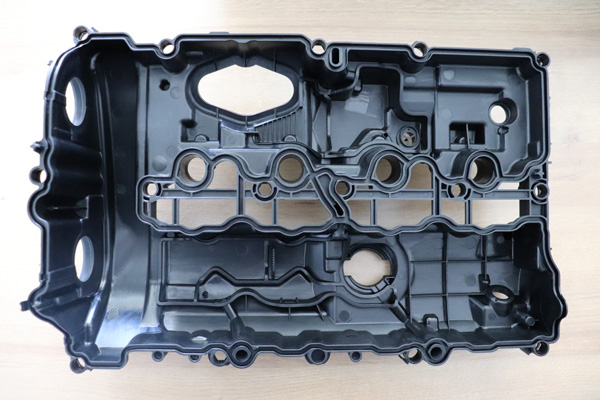

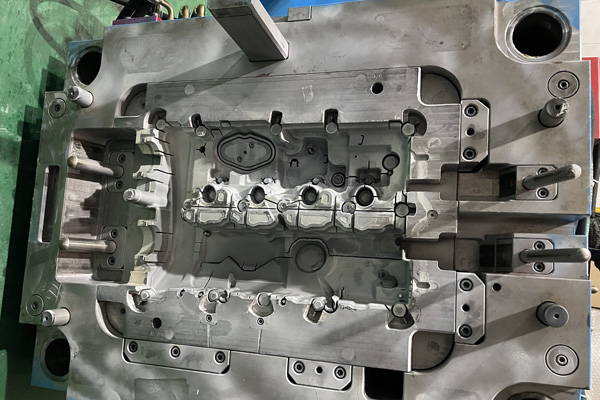

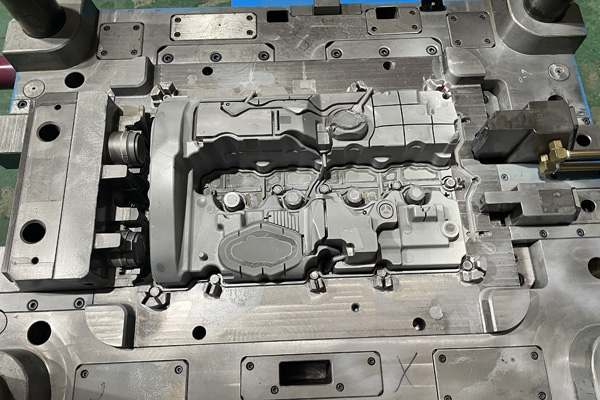

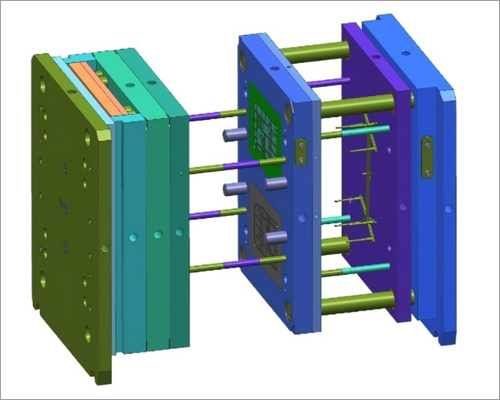

June 5, 2022The market is driven by regulatory demands for lower CO₂ emissions. We assisted the client in switching the material for this engine cover from steel to engineering plastics in the injection molding project, which reduced weight and cost by up to 60% compared to steel without sacrificing strength. This is a very complex tool. The material is nylon filled with 35% fiber glass.

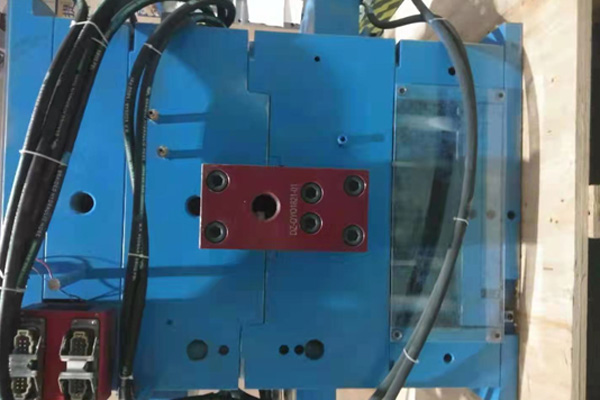

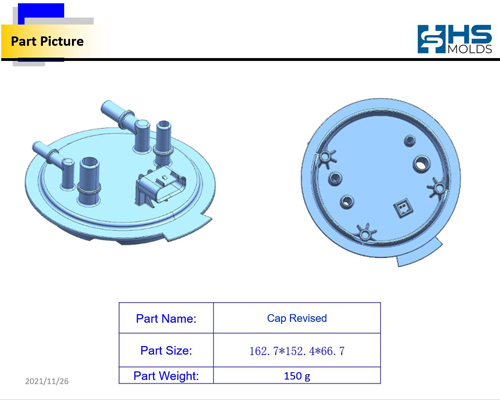

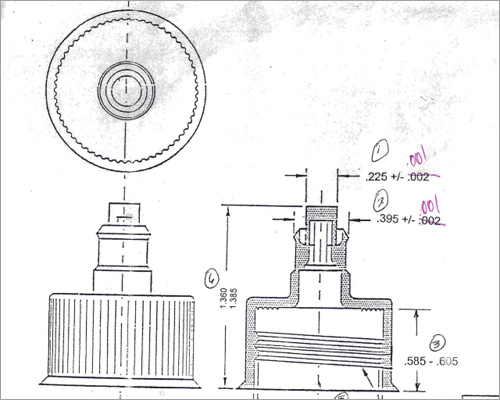

We have been making complex molds for the automotive market, covering engine cooling radiators, energy coolant radiators, and reservoir caps.

The market’s future is moving to electricity, and the solution is light-weighting.

We support automotive and industrial manufacturers to produce re-invented technology for optimized use.