Importance of wall thickness for defect-free plastic.

September 19, 2021

HS-Mold company breakthroughs challenging supply chain despite covid outbreaks

October 28, 2021

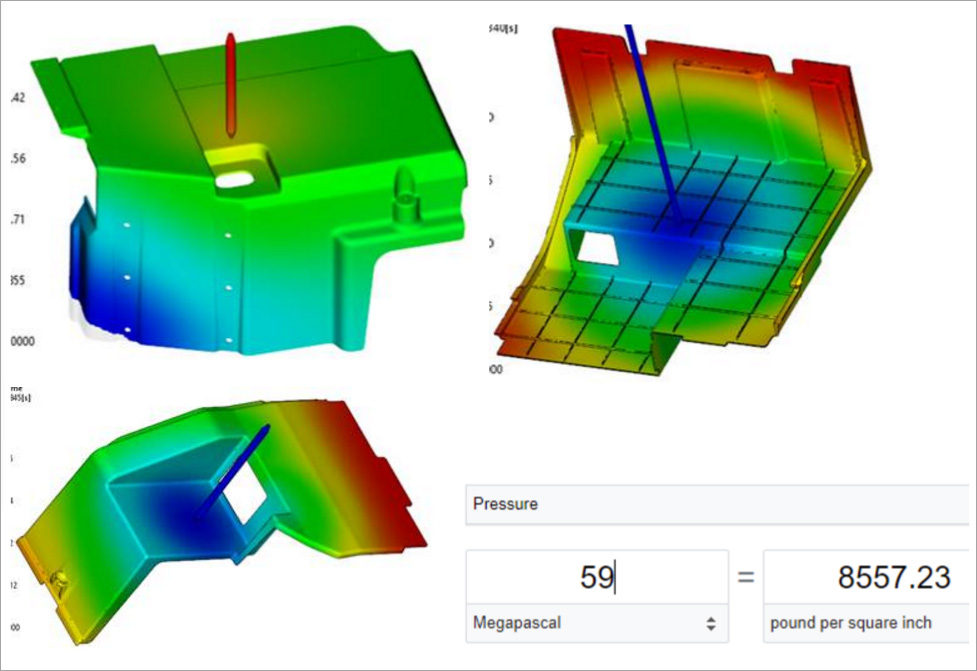

It’s pre-manufacturing software designs in the injection molding. Mold flow analysis (MFA) allows to draw model of molds for final products development.

Improve Plastic part design for injection molding

Designers could solve issues as listed below using Moldflow Analysis

1. It tells you whether or not your part could be filled with a selected material. This is a crucial issue that most part designer care about. Mold flow analysis enables designers to test the physical and

chemical characteristics of different manufacturing materials prior to mold making, ensuring that the ideal material is used to align the part’s composition with its intended application. Besides, mold analysis examines how resins flow with certain temperatures and injection pressures (as shown in the picture). As material cools it begins to harden and this is why gate pressure increases. The higher the pressure, the more difficult the fill, which translates to greater concern about weak knit lines (contributing to poor part integrity), flash, sink, and shorts.

2) Mold analysis can help to determine the right wall thickness. The minimum wall thickness is directly related to the cost of plastic parts. Material cost often accounts for 40% of the total cost, therefore the use of thin-wall plastic parts can greatly reduce the cost of plastic parts and shorten the cooling time. Both resin and injection molding cost could be reduced with the right wall thickness while production efficiency enhanced.

3) Mold analysis aids in the positioning of the gate or gates on your part. The position of injection gate is crucial to the part quality. Moldflow analysis could help to determine the best gate location at design stage without harming the cosmetic look.

4) Optimize the design of Plastic Injection Mold

One of the key advantages of mold flow analysis is that it can help mold engineers pinpoint specific tooling design issues upstream, thereby optimizing plastic mold design early and reducing downstream costs associated with retooling.

5) Further, it can help ensure that mold cavities are filled with consistency, mitigating the occurrence of air traps as well as surface defects like sink marks or weld lines. It may also help engineers determine the optimal location for gates — the area where the thermoplastic is injected into the mold cavity — reducing the need to re-tool molds for greater efficiency.

Here at HS Molds, we run Moldflow analysis for every injection mold/molding project so that our engineers are able to test the physical and chemical characteristics of different manufacturing materials prior to production.