Selective tool steel – The best guide

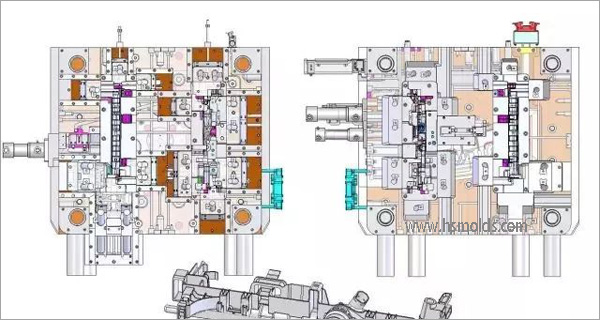

September 11, 2021Injection molds for expansion tank with mounting plates

Expansion tank is one of the most complex automotive parts with different mounting plates.

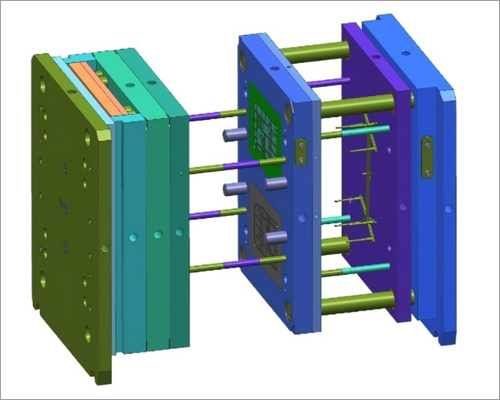

Expansion tank is one of the most complex automotive parts. To handle the injection tooling project of Radiator Expansion Tank Mounting Plate, it requires consolidating force from each team including mold flow/design/machining/QC. And the whole team must acquire wealth of experience, otherwise the critical dimensions are difficult to be achieved and mold has to be changed again and again. For most companies, the warp issue caused by plastic PA66+30GF is always a big challenge . If not done right, it is common to dump away core and cavity and replace new ones.

Mold Flow. Use Mold flow to calculate the warp and gate location with the size normally between4-6mm. Now here is the question, a lot of mold makers complaint about that the result from Mold flow differs greatly with actual result. According to our years of experience, mold flow reading is feasible, but it requires more experience as how to understand the warp/torque/twist.

3.Modify part warp. Modify part print of Auto Transmission Coolant Recovery Tank Mounting Plate based on mold flow result and actual experience. We have built dozens of these plastic molds for Radiator Mounting Plate for Expansion Tank and accumulated rich experience in this aspect.

4.Mold Mechanism:①When designing PL, we need to follow one principle, PL could not be changed when adding or reducing plastic②As much cooling as possible。③Make small inserts for the main area where dimensions are critical so that it is easy to replace if necessary.

6.Fitting:①For oil cylinder mold, it is easy to get burnt. The fitting needs to be alittle.

7.Loose:②It is easy to create flash with this plastic, so we have to CNC on the flat surface while leaving enough wall stock. ③Place slides to the cavity to fix the gap.

HS plastics is your single solution for complex AUTOMOTIVE projects! Contact us now for more detail.

Well, it is a science to develop injection molds for Custom Molded Mounting plate for Expansion Tank. Let’s hear about your opinion!