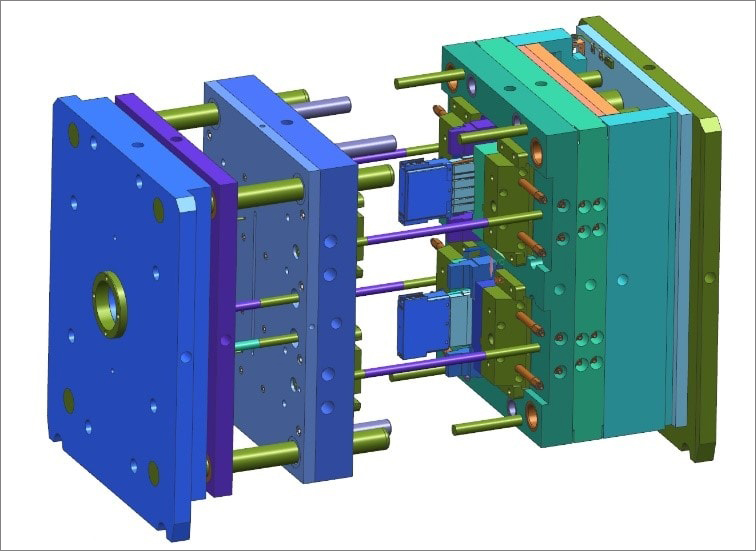

Mold Engineering Service

We provide product design and engineering assistance to help you develop your plastic injection molding projects.

Why You need Mold Design for plastic molding?

The injection molding process is a cost-effective method to produce precision parts. A good mold design is very important. With a good design, parts can be made consistently and with quality. But, without a good design, Processing mistakes can occur and extremely costly.

We Will Assist You with Design Optimization

Our design engineer’s team has over 18 years of experience not only designing molds but also building them. Our process for designing injection molds starts with a detailed DFM (design for manufacturability) that includes solutions to resolving challenges and obstacles that may arise with complex projects, as well as recommendations for solving plastic engineering problems.

Our prototyping and NPI stages allow proof of concept for mold design to create a finished plastic part. And we are also taking into consideration how the entire mechanical assembly will come together with purchased and custom components, helping you bring new plastic products into the market at accelerated speeds.

Our Engineering Service

Except for tooling design of new injection molds, we are the molding company that provides product design and engineering assistance to help you develop your plastic injection molded projects.

- Signed NDA to protect your design

- New Product DFM Report

- Moldflow Analysis

- Design HASCO/DME/Misumi Standard

- Software:AutoCAD, UG, Pro-E, PM